|

|

|

DQ Series

DQ Series |

| NON-FLAMMABLE

FIXED WIRE-WOUND POWER RESISTOR |

| DQ

SERIES |

|

|

RATED

WATTS |

DIMENSIONS(m/m) |

|

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

K |

L |

M |

O |

P |

Q |

|

| 75W

|

110

|

25

|

16

|

30

|

8

|

150

|

5

|

18

|

6

|

166

|

58

|

1.2

|

6

|

27

|

M5X135 |

M5X135 |

|

|

90W |

90 |

28 |

18 |

32 |

8 |

130 |

5 |

19 |

6 |

146 |

60 |

1.2 |

6 |

27 |

M5X115 |

M5X115 |

| 120W

|

110

|

28

|

18

|

32

|

8

|

150

|

5

|

19

|

6

|

166

|

60

|

1.2

|

6

|

27

|

M5X135 |

M5X135 |

|

150W |

140 |

28 |

18 |

32 |

8 |

180 |

5 |

19 |

6 |

196 |

60 |

1.2 |

6 |

27 |

M5X165 |

M5X165 |

| 180W

|

160

|

28

|

18

|

32

|

8

|

200

|

5

|

19

|

6

|

216

|

60

|

1.2

|

6

|

27

|

M5X185 |

M5X185 |

|

225W |

195 |

28 |

18 |

32 |

8 |

235 |

5 |

19 |

6 |

251 |

60 |

1.2 |

6 |

27 |

M5X230 |

M5X230 |

| 240W

|

185

|

35

|

24

|

36

|

10

|

225

|

5

|

19

|

8

|

245

|

76

|

1.6

|

6

|

34

|

M5X210 |

M5X210 |

|

300W |

210 |

35 |

24 |

36 |

10 |

250 |

5 |

19 |

8 |

274 |

76 |

1.6 |

6 |

34 |

M5X245 |

M5X245 |

| 375W

|

210

|

40

|

25

|

38

|

12

|

250

|

5

|

20

|

8

|

274

|

78

|

1.6

|

6

|

34

|

M5X245 |

M5X245 |

|

450W |

260 |

40 |

25 |

38 |

12 |

300 |

5 |

20 |

8 |

320 |

78 |

1.6 |

6 |

34 |

M5X295 |

M5X295 |

| 600W

|

330

|

40

|

25

|

38

|

12

|

370

|

5

|

20

|

8

|

395

|

78

|

1.6

|

6

|

34

|

M5X365 |

M5X365 |

|

750W |

330 |

50 |

35 |

50 |

12 |

380 |

6 |

25 |

9 |

400 |

100 |

1.6 |

8 |

40 |

M5X365 |

M5X365 |

| 900W

|

400

|

50

|

35

|

50

|

12

|

450

|

6

|

25

|

9

|

470

|

100

|

1.6

|

8

|

40

|

M5X435 |

M5X435 |

|

1000W |

460 |

50 |

35 |

50 |

12 |

510 |

6 |

25 |

9 |

530 |

100 |

1.6 |

8 |

40 |

M5X495 |

M5X495 |

| 1200W

|

460

|

60

|

40

|

55

|

15

|

515

|

6

|

30

|

10

|

535

|

110

|

1.6

|

10

|

50

|

M5X495 |

M5X495 |

|

1500W |

540 |

60 |

40 |

55 |

15 |

595 |

6 |

30 |

10 |

615 |

110 |

1.6 |

10 |

50 |

M6X580 |

M5X580 |

| 2000W

|

650

|

65

|

42

|

62

|

15

|

702

|

6

|

30

|

10

|

722

|

115

|

1.6

|

10

|

50

|

M6X690 |

M5X690 |

| DQ

Resistor Series |

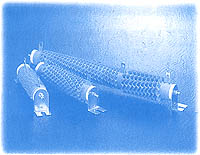

| A tubular ceramic

resistor which has two terminals is wound with a resistance element

consisting of a wave-shaped alloy ribbon. A high-temperature,

non-flammable resin insulation is applied after cooling and drying

through a high-temperature process and then the component mounts are

attached. The resistance value range is relatively low due to alloy

material limitations (See the D resistor series if high resistance

values are required). This product supports the use of numerous

taps, is low impedance, and can be fabricated in various shapes to

support a wide range of resistor applications. These resistors are

suitable for educational modeling applications, load testing,

industrial machinery, electric power distribution, instruments and

automation control installations, dtc. For custom specifications,

please contact us to discuss the details. |

|

FEATURES |

- Smoke is emitted during the

initial conductance of electricity by the resistor, but this is

normal and the component is safe to use.

- Resistor coating complies with

the U.S. UL-94 non-flammability test, Class V-0, a continuous

combustion period of zero seconds.

- Corrosion-proof, with superior

heat resistance characteristics; low temperature coefficient and

change in resistance is directly proportional.

- Excellent windings, supports

placement of numerous taps, low impedance, and shape can be varied

to produce a wide range of resistor types.

- Good heat dissipation and compact

size with high current capability; the same appearance as the D

resistor series, but 1.5 times larger in dimension.

- Excellent flexibility. Special

production orders accepted to accommodate individual customer

specifications and requirements.

|

|