|

|

|

MO系列

MO系列 |

| MO Series Flame-Proof Type Metal Oxide Film Resistors |

| METAL OXIDE FILM RESISTORS MO Series (Flame-Proof Type) |

1/4W, 1/2W, 1W, 2W, 3W, 5W

MO-25, MO-50, MO-100, MO-200, MO-300, MO-500 |

| INTRODUCTION |

| These Metal Oxide Resistors offer excellent performance in applications where stability and uniformity of characteristics are desired. They provide lower cost alternatives to Charbon Composition Resistors and General Purpose Metal Films. Metal Oxide also can replace many low power General Purpose Wirewound applications, saving both money and time, with shorter delivery cycles. |

|

|

| FEATURES |

- High power-to-size ratio for significant space savings.

- Excellent long-term stability.

- Complete flameproof construction.

- High surge/overload capability.

- Wide resistance range : 1 Ω ~ 1MΩ

- Standard tolerance : ±5% , ±2%

|

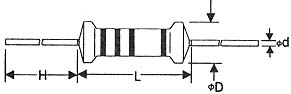

| DIMENSIONS: |

| STYLE |

DIMENSION (mm) |

POWER RATING

(Watt) |

VALUE

RANGE |

| L |

ψD |

H |

ψd |

| MO-25 |

6.0 ±0.2 |

2.3 ±0.3 |

28 ±2 |

0.5 ±0.02 |

1/4W |

1Ω~1MΩ |

| MO-50 |

9.5 ±0.5 |

3.2 ±0.5 |

26 ±2 |

0.6 ±0.02 |

1/2W |

1Ω~1MΩ |

| MO-100 |

11.0 ±0.5 |

4.5 ±0.5 |

35 ±2 |

0.7 ±0.02 |

1W |

1Ω~1MΩ |

| MO-200 |

15 ±0.5 |

5.0 ±0.5 |

32 ±2 |

0.8 ±0.02 |

2W |

1Ω~1MΩ |

| MO-300 |

17 ±0.5 |

6.0 ±0.5 |

32 ±2 |

0.8 ±0.02 |

3W |

1Ω~1MΩ |

| MO-500 |

25 ±1.0 |

8.0 ±0.5 |

35 ±3 |

0.8 ±0.02 |

5W |

1Ω~1MΩ |

|

|

ELECTRICAL CHARACTERISTICS |

| Style |

MO-25 |

MO-50 |

MO-100 |

MO-200 |

MF-300 |

MO-500 |

| Power Rating 70 o C |

1/4W |

1/2W |

1W |

2W |

3W |

5W |

| Operating Temp. Range |

-55 o C ~ +155 o C |

| Max. Working Voltage |

250V |

350V |

350V |

350V |

500V |

500V |

| Max. Overload Voltage |

400V |

700V |

700V |

700V |

1000V |

1000V |

| Dielectric Withstanding Voltage (AC) |

300V |

350V |

350V |

500V |

1000V |

1000V |

| Max. Intermittence Overload Voltage |

400V |

700V |

1000V |

1000V |

1000V |

1000V |

| Value Range ±1%, ±2%, ±5% |

1 Ω ~510K Ω |

| Temp. Coefficient (by Type) |

±300ppm/ o C |

|

| * The listed resistance range for standard resistance, below or over this resistance is on request. |

|

ENVIRONMENTAL CHARACTERISTICS |

| PERFORMANCE TEST |

TEST METHOD |

APPRAISE |

| Short Time Overload |

JIS-C-5202 5.5 : 2.5 times RCWV for 5 seconds |

±(1%+0.05 Ω) |

| Dielectric Withstanding V. |

JIS-C-5202 5.7 : in V-Block for 60 seconds |

By Type |

| Temperature Coefficient |

JIS-C-5202 5.2 : -55 o C ~+155 o C |

MAX. 300ppm/ o C |

| Insulation Resistance |

JIS-C-5202 5.6 : in V-Block |

± 1000 M Ω |

| Solderability |

JIS-C-5202 6.5 : 230 o C for 5 ±0.5 seconds |

95% min. coverage |

| Resistance to Solvent |

JIS-C-5202 6.9 : Trichroethance for 1 min. with ultrasonic |

no deterioration |

| Terminal Strength |

Direct load for 10 sec. In the direction of the terminal leads |

±2.5KG/24.5N |

| Pulse Overload |

JIS-C-5202 5.8 : 4 time RCWV 10000 cycles(1 sec.on, 25 sec.off) |

±(2%+0.05 Ω) |

| Load Life in Humidity |

JIS-C-5202 7.9 : 40 ±2 o C, 90~95% RH at RCWV for 1000 hrs

(1.5hrs. on, 0.5 hrs. off) |

±(5%+0.05 Ω) |

| Load Life |

JIS-C-5202 7.10 : 70 o C at RCWV for 1000hrs (1.5hrs.on, 0.5hrs.off) |

±(5%+0.05 Ω) |

| Temperature Cycling |

JIS-C-5202 7.4 : -55 o C~room temp.~155 o C~room temp for 5 cycle |

±(1%+0.05 Ω) |

| Soldering Heat |

JIS-C-5202 6.4 : 350 ±10 o C for 3 ±0.5 seconds |

±(1%+0.05 Ω) |

|

|

|