|

|

|

CR標準系列

CR標準系列 |

| CR Series Carbon Film Resistors |

| CARBON FILM RESISTORS CR Series |

| 1/6W; 1/8W, 1/4W, 1/2W, 1W, 2W, 3W, CR-12, CR-25, CR-50, CR-100, CR-200, CR-300 |

| INTRODUCTION |

Featuring consistency and stably-controlled, these carbon film resistors with reasonable prices are widely & largely used in the electronic, electrical and information industries.

This resistor is a ceramic bar tightly coated with a carbon film which is composed of carbon separated from organic compound through the treatment of high-temperature vacuum. After the carbon-coated bar is connected with proper joint and engraved with grooves, its surface is finished with epoxy resin so that the bar is enclosed with a protective film. |

|

|

| FEATURES |

- Industry's lower cost and deliver from stock.

- Exceptional long-term stability.

- Exceeds carbon comp MIL-R-11 performance.

- Standard tolerance:

2%, 2%,

5%

5%

- Variety of packing-bilk, strip pack, 26mm and 52mm tape and reel, cut and formed or radial Pana.

|

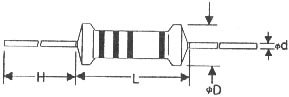

| DIMENSIONS: |

STYLE |

DIMENSION (mm) |

POWER RATING (Watt) |

VALUE RANGE |

L |

D D

|

H |

d d

|

CR-12 |

3.3  0.4 |

1.8  0.3

|

28  2

|

0.43  0.05 |

1/6W ; 1/8W |

1  ~10M

|

CR-25 |

6.3  0.5 |

2.3  0.3

|

28  2

|

0.5  0.05 |

1/4W |

1  ~10M

|

CR-50 |

9.0  0.5

|

3.2  0.5 |

26  2

|

0.6  0.05 |

1/2W |

1  ~10M

|

CR-100 |

11.5  1.0 |

4.5  0.5

|

35  2

|

0.7  0.05 |

1W |

1  ~10M

|

CR-200 |

15.5  1.0 |

5.0  0.5

|

32  2

|

0.8  0.05 |

2W |

1  ~10M

|

CR-300 |

17.5  1.0 |

6.0  0.5

|

35  2

|

0.8  0.05 |

3W |

1  ~10M

|

|

| ENVIRONMENTAL CHARACTERISTICS |

Style |

CR-12 |

CR-25 |

CR-50 |

CR-100 |

CR-200 |

CR-300 |

Power Rating 70 |

1/6W ; 1/8W |

1/4W |

1/2W |

1W |

2W |

3W |

Operating Temp.Voltage |

-55℃ ~ +155℃ |

Max. Working Voltage |

150V |

250V |

350V |

500V |

500V |

600V |

Max. Overload Voltage |

300V |

500V |

700V |

1000V |

1000V |

1000V |

Dielectric Withstanding Voltage |

300V |

500V |

700V |

1000V |

1000V |

1000V |

T.C.R. (PPM) |

CR-12/CR-25/CR-50 |

CR-100/CR-200/CR-300 |

100KΩdonw |

100KΩ~1MΩ |

1MΩup |

100KΩdown |

100KΩ~1MΩ |

1KΩup |

+350/-500 |

+350/-700 |

+350/-1000 |

+350PPM |

+350/-500 |

+350/-1000 |

|

| ENVIRONMENTAL CHARACTERISTICS |

| PERFORMANCE TEST |

TEST METHOD |

APPRAISE |

| Short Time Overload |

JIS-C-5202 5.5 : 2.5 times RCWV for 5 seconds |

(0.75%+0.05 (0.75%+0.05

) )

|

| Dielectric Withstanding V. |

JIS-C-5202 5.7 : in V-Block for 60 seconds |

By Type |

| Temperature Coefficient |

JIS-C-5202 5.2 : -55℃ ~+155℃ |

By Type |

| Insulation Resistance |

JIS-C-5202 5.6 : in V-Block |

1000 M

1000 M  |

| Solderability |

JIS-C-5202 6.5 : 230℃ for 5  0.5

seconds 0.5

seconds |

95% min. coverage |

| Resistance to Solvent |

JIS-C-5202 6.9 : Trichroethance for 1 min. with ultrasonic |

no deterioration |

| Terminal Strength |

Direct load for 10 sec. In the direction of the terminal leads |

2.5KG/24.5N 2.5KG/24.5N

|

| Pulse Overload |

JIS-C-5202 5.8 : 4 time RCWV 10000 cycles(1 sec.on, 25 sec.off) |

(2%+0.05 (2%+0.05

) )

|

| Load Life in Humidity |

JIS-C-5202 7.9 : 40  2℃, 90~95% RH at RCWV for 1000 hrs 2℃, 90~95% RH at RCWV for 1000 hrs

(1.5hrs. on, 0.5 hrs. off) |

(3%+0.05 (3%+0.05

) )

|

| Load Life |

JIS-C-5202 7.10 : 70℃ at RCWV for 1000hrs (1.5hrs.on, 0.5hrs.off) |

(3%+0.05 (3%+0.05

) )

|

| Temperature Cycling |

JIS-C-5202 7.4 : -55℃~room temp.~155℃~room temp for 5 cycle |

(1%+0.05 (1%+0.05

) )

|

| Soldering Heat |

JIS-C-5202 6.4

: 350  10℃ for 3 10℃ for 3  0.5

seconds 0.5

seconds |

(1%+0.05 (1%+0.05

) )

|

|

|

|